Please note that all parts had to come from

a set list of materials, so some odd piecing and skarfing was necessary to

comply. You, however, can just buy longer boards! Where there are dimensional

differences between this and the day by day prototype building diary, these are more accurate.

Last updated March 17, 2002. Here is the Duckworks

build of Summer Breeze in stitch and glue.

Summer Breeze

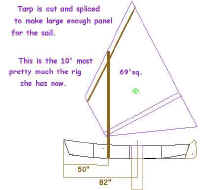

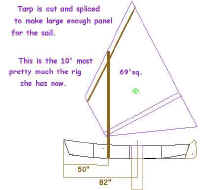

My entry into the Duckworks contest is an 11'8" long 50" beam 16" sides,

high capacity skiff reminiscent of the turn of the century flatiron skiffs. I

know the contest guidelines urged us to stress specific use, but since this was

conceived as a community boat building craft, what I've tried for is versatility

and ease of construction. No lofting is required and all saw cuts are straight.

The "bump" where the sides rise to the transom is smoothed out with

plane, rasp or sander. The chine log, PL premium and bronze nail construction

keeps young fingers out of Epoxy and glass, though she can be stitch and glued

and glass sheathed if conditions warrent.

She's a pleasure to row, and I have several times

hit 7.5 knots with her humble polytarp lug sail in moderate breezes. Though I've

only had my wife and I, our dog and a picnic in her as yet, her leeboard creates

wide open sprawling space enough for a bed roll to a dedicated small boat

camper.

Though I didn't have more than an electric trolling

motor in mind when designing her, one builder has had fun with a 4 horse kicker

on his version of this boat. The USCG math recommends no more than 3 horse

power. The calculations put her in the 5 horse category, but flat bottom hard

chined boats get bumped down a notch to 3 hp due to tendencies to flip in hard

turns. More detailed

building notes:

|

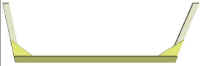

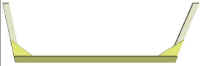

Here are the three views. I'm

no artist so the photos of the model and the boat will have to do. |

And here is the way the sheets of ply and board stock

are utilized.

|

You'll notice that the waste in the side layout sheet is the saw

dust from the kerfs. This sheet also provides butt blocks, skeg, oar blades

and quarter knees. |

|

The rotated triangles in the bottom layout

is what make it possible to get such a large bottom section from one

sheet. Gussets, mast step, leeboard backing and bow butt blocks also come

from this sheet. |

|

Here's photo of the bow

triangles and their butt blocks. |

|

Using solid stock for the transom

allows maximum bottom and sides from ply, and makes for a respectable capacity

skiff without going to a pram bow. |

|

The stem can be made of solid

stock, but this resaw sandwich method uses the least wood. The ply gussets

are sandwiched between the bottom and side frame members. |

|

This is the half frame dimensions for laying it

out.

This is the half frame dimensions for laying it

out. |

|

Here are the sketches of

the frame, showing pre-cut lengths and the temporary cross brace. |

|

The shaded version should make it clearer how the gusset

is sandwiched. The shaded version should make it clearer how the gusset

is sandwiched. |

|

|

Showing "limber"

holes (drain holes) for external chine logs or internal chine logs. |

Transom:

(Details on notes page.)

(Details on notes page.)

Gunnels and chine logs...

|

The photos show split gunnel and

inwale set up, but this single gunnel is simpler and sufficient. The chine

log is not necessary if the bottom is stitched to the sides. |

|

I had to laminate a couple of pieces from one of the

1" boards and scarf to the 2x4 to get the 10 foot mast I wanted. One pole

is used for the upper spar of the lug sail. I was going to use the other for

the sprit boom, but someone mentioned that in this contest, a row boat needed to make the oars from

the material (you can specify a purchased motor, but not oars?) So now the sail

is either loose footed in the chine log version, or if she's stitch and glued

together the chine log material can be used as the sprit boom. Sail making

details are HERE. |

|

The laminated ply skeg

slips into a slot in the keel making fitting it to the bottom simpler. |

|

In spite of all the

straight cuts, to my eye, her finished lines are sweet and flowing. One of the small

miracles of boat building. |

|

Here's a screen shot of Gregg's Hull program showing the

displacement at 569. The water line just touches the stem and transom

here. At 650lbs it not even an inch higher, but seems like pushing it. Displacement, of course includes the weight of the hull. Capacity is how much

she can hold, which is over and above the weight of the hull. Since the finished boat weighs about 60 lbs, I've

estimated her capacity at 500

lbs. This is an upper limit figure and I expect her rarely to be that loaded. |

|

If you like playing with

paper models I've put all her parts in one image here. If you print it out

on file folder stock (legal size is what I like) you can cut fold and tape

it. Leave the transom attached and fold it. Also leave the sides attached

where they touch the bottom. Tape the frame where indicated. Great aid to

the imagination! |

Floatation

& Safety

|

Being all wood, this skiff wont sink, however

it wont float high enough when swamped to make self rescue very

feasible. Foam floatation can be easily added making use of construction

foam available in 4'x8' sheets in thicknesses from 3/4" to 2".

(Blue board behaves better during cutting than the white stuff, which

sheds little balls.) Cut pieces to fit the bow, stern and under the seat

and mast partner. Make a cardboard pattern to guide you. Triangle for

the bow, trapezoid for the stern, etc. The pieces can be stacked and

either glued or double stick taped together, then wrapped in either

polytarp, or canvas, hot melt glued or velcroed. 3/8" stainless

screw eyes (or hooks) can be placed strategically in the transom, stem,

chine logs, underside edge of the seat, etc. to take 1/4" line (or

bungee cord) to lace them in place. Done right, the bow and stern

bundles can double as seats or sprawling back rests. Stay safe.

Particularly in colder waters, add floatation.

|

|

She trims fine for rowing. |

Ultra Light Rowing Version -

This is a fantasy of an ultra light version that is a simple approach to

lapstrake building. The lap gluing is done flat on the floor, the gunnels and

the chine logs are attached and the side is bent as an assembly. (I know this

sounds far fetched but Steve Redmond used this approach in his skiff Whisp.) The side sheet

is 1/8" ply. 1/2" overlaps provide added stiffness. The gunnels are

notched (1/8" x 3/4") to enclose the top of the sides, a la Herb

McLeods OSS. This seals the top of the ply sides and extends the height of the

side 3/4" to make up for most of the inch lost in the laps.

|

In this case I would

temporarily hold the side panels together with duct tape while cutting the

strakes. The bow and stern are divided in thirds then a batten or

PVC pipe is used to draw the curves of the strakes. Cut with a thin saw

blade, saber saw, or even a matt knife. 1/4 staples can be used to

"clamp" the laps. The strakes could be skarfed with epoxy and

2" tape rather then 1/8" butt blocks. |

|

I confess this board layout

was done before the Duckworks contest so it calls for one 12 foot 2x4. In

keeping with the rules, we will scarf it from the two 8 footers allowed. For oar locks I

glue 3/4" thick blocks to the gunnels with stainless deck screws,

then drill a 1/2" hole lined with half a brass grommet for canvas

works. This really works! |

A couple of sketched views.

A couple of sketched views.

|

This was the proof of concept

1/4 sized model done in 1/8" |

|

More detailed

building notes:

Now for some legal

stuff:

I am neither trained nor

certified in naval architecture. This boat is intended to be built by the

author, of modern materials and is intended to be sailed and rowed on protected

waters. The designer takes no responsibility for the action of any persons

making use of this design for their own purposes; neither does this designer

make any claims that this craft meets any regulations set by any authority

anywhere in the world. Contact the designer David J. Beede at 115 Cygnet Lane,

Melrose Florida, 32666 USA or by email David Beede simplicityboats.

©

David J. Beede 2000

Back to Simplicity Boats Home page.

This is the half frame dimensions for laying it

out.

This is the half frame dimensions for laying it

out.

The shaded version should make it clearer how the gusset

is sandwiched.

The shaded version should make it clearer how the gusset

is sandwiched.