October 10th - Day Three

Okay, here's what's up today. I decided it best to fit the full sheet of ply on the back and see how much of the hull it covered.

Here I'm lining up the ply with the transom.

Now I mark where it falls on the bow. This showed me I needed to alter the size of the triangles, and also shift the transom 3/4" forward before gluing.

Then I removed the dry fit stem.

Rounded it on my router that I've mounted flush in a bench top. I use a carbide 1/2" radius corner round bit. I put a bead of PL Premium down the grooves slid the sides into place and tacked them with 1/2" staples until the glue grabs. (I almost glued it on upside down. That would have been a big oops!)

I also removed the dry fit stern after having marked the bottom angle on it. I shaved that angle with a plane. Here I've clamped stops to help align it while gluing.

Here it is glued and nailed. I used #12 by 1 1/4" bronze ring nails, about two inches apart - seven nails per side. I pre- drilled for the nails.

Chine logs....

First a confession. You know how sometimes when you make one thing simpler, you may two things more complicated? Well it looks like I might have done that. I love this slotted stem for the ease of gluing sides and for the nice curved cut water you can make with little effort. However, it turns out that the chine logs and the gunwales now have to have a compound angle cut on them to fit the stem. So here's a choice point for you. You can use a normal internal stem sawn at 27 degrees, and skip this compound angle stuff or you can do what I did. Get out your bevel gauge.

First you measure this angle of sides to stem

Then mark this angle of the sides into the stem.

Then cut it with your saw of choice. (I love these Japanese pull saws)

Then dry clamp the chine log in place.

If it fits pre drill for the #14 by 7/8" bronze ring nails every 6"s.

Unclamp half the chine log, apply glue and re-clamp and hammer the nails home. Hold a sledge or heavy weight behind where you hammer as a "bucking iron." It absorbs the impact of your hammer and makes it all much easier.

Do the same to the other side.

Now cut the triangles from the back sheet of ply. In spite of my careful drawings and models it seems the long leg will work better at 30" instead of 28" that I originally indicated. The short leg is still 12".

I use the Japanese pull saw again for this.

Next I'll position these on the bow and mark them for gluing the butt blocks.

This would all be a bit faster if I wasn't working out the design as I do the building. I'm sure the next one will go faster.

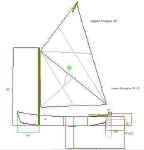

I also worked on the sail rig and the leeboard and rudder. Here's a glimpse of my sketch so far.