| Joint test details ... |

Here I will give the details of how each of the test joints were made, materials, sources etc.

For those of you unfamiliar with PL Premium polyurethane adhesives - they are construction adhesives related to 3M 5200 but much less expensive. See our PL Premium page for statistics and testimonial.

|

9/2/02

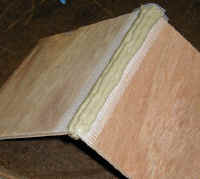

The first material I am using is 1/4" exterior luan plywood. (3 ply - 1 thick inner ply and 2 thin outer plies.) Partly because many small home built boats are made from it, and partly due to it being cheap and available. The ply is cut into 8" squares, and the joints are made at a 15 degree angle. (To simulate average small boat flare.) |

1. 1.

|

1.

The epoxy test panel was made with 2:1 Epoxy from U.S.Composites with slow hardener. |

|

The fill used in the fillet was wood flour. 2"

5.7 oz. glass tape from Glen

L Marine.

|

|

2. The external chine logs were made from 1x2 stock split at 15 degrees. Fasteners are 3/4" #14 bronze ring nails. (Glen L) Chine log is attached to the side with Titebond II and nails. The "bottom" is attached with PL Premium and nails. (Nails are spaced 3.5 inches apart.) 3. this is like the above but with PL Premium used for both the side and bottom joint.

|

4. 4.

|

4. This test panel is done the way some are using PL on small boats. A good sized PL Premium fillet on the inside and mesh drywall tape embedded on the outside. |

|

One of the challenges of PL Premium is its tendency to bubble as it cures. One way to minimize it is to cover it with plastic as it cures. |

|

As you can see here it doesn't entirely cure the bubbling but the results become a little less unsightly. |

|

In place of fiberglass cloth tape the much less substantial fiberglass mesh tape sold for drywall joints is applied in two layers, offset slightly. This tape is slightly tacky and adheres pretty easily to a gently rounded corner (approximately 3/8" radius) |

|

Three beads of PL Premium are applied. |

|

And spread with a plastic spatula - the kind used for Bondo body filler. |

|

Some easy release tape is used to minimize bubbling on the outside joint. This painters tape is called "Perfect Release" which is sold at Wal-Mart. |

|

When the tape is removed, bubbling is evident, but they were

forced into cavities by the tape, rather than bubbles rising above the

surface. (Perhaps they will be filled later.)

|

5. 5.

|

5.

PL Masonry inside (filleted with a spoon) and mesh tape imbedded in PL Masonry outside. The great advantage of PL Masonry is that it does not bubble while curing. However full cure requires a week rather than overnight. For a demo of its amazing flexibility and "memory effect" go here.

|

|

9/03/2002

After the inside fillet dried overnight, I rounded the outside corner and applied two layers of fiberglass mesh drywall tape. The layers were off set slightly. |

|

I applied 3 beads of PL Masonry sealant. |

|

I used a plastic spatula (the kind you spread bondo with) to spread the PL and force it into the tape weave. |

|

The process feels a bit like frosting a cake. Knowing the challenge of sanding cured PL Masonry I was trying for the smoothest possible final coat. |

6. 6.

|

6.

This is the joint with a PL Premium bead on the inside. I didn't touch it after application and found it didn't bubble in any noticeable way at all, despite the heat and humidity. |

|

I trimmed the joint and sanded it round with 80 grit palm sander. |

|

Again two layers of tape. |

|

I tried to apply more PL closer to the apex to facilitate spreading. |

|

It still didn't quite fill the weave entirely. |

|

Two more beads were needed again. |

|

That helped, and I also trimmed the edge of the spatula with a razor blade along a straight edge, producing a smoother surface. |

Back to Stress testing the ply joint assemblies.

Back to Methods and Materials